The Legendary Cider

One sip and you’ll understand why our cider has stood apart as uniquely delicious for generations.

People often ask us what makes our cider taste so good. Here are a couple hints: It starts with selecting really good fruit . . . and then, it’s all about the details — the cider press (it’s a one-of-a-kind), the process and the patience. And that’s why you can’t get this taste, this experience, anywhere else.

The Apples: The Right Combination at the Right Time

Our cider is smooth, crisp, and loaded with apple flavor. That’s just the way we like it, and generations of Yates patrons agree that that’s how cider should be! We use nothing less than premium fruit to make cider, and you can taste and see the difference in every cup.

Apples come in all shapes, sizes, flavors, and varieties. Each variety has a different flavor characteristic, and each variety has its own harvest date in the fall season. The season starts in late August or early September with late summer apples like Ginger Golds and Paula Reds, which are lighter in juice color and have a tarter flavor. As the season progresses, more varieties ripen. As each week passes, different cider flavors can be blended to create more intriguing tastes. By mid-October, as many as 10 different varieties of apples can be combined to make some pretty amazing flavor!

Cortland

Empire

Gala

Honeycrisp

Jonathan

McIntosh

Northern Spy

Jonagold

Golden Delicious

The Process: The Classic That Stands the Test of Time

1876. That’s the year of our first recorded cider sale.

1894. That’s the year our 26-inch water turbine was installed.

1 year before the sound of radio was ever heard.

9 years before anyone flew in an airplane.

33 years before anyone ever stared at images on a television screen.

And it’s still used today. It’s the same turbine that was used way back when to power our press in order to make our cider. It’s a part of what makes the Yates Cider Mill so unique.

In fact, the well-known decorative water wheel outside of the mill, which was made and installed by former owner Charles Posey, represents what we stand for. It’s called an “undershot” water wheel and is a nod to the original source of water power for the mill. It turns by water power and is the type of wheel that was used to power the original mill before 1894.

We make cider like we did when we first started making it in 1876. It’s our tradition. We won’t change, and we don’t want to change. It’s what makes our process unique and our cider so good. It’s what makes the difference between making cider and creating an experience.

Not only do we have an amazingly loyal local following, but Yates Cider Mill is also a popular attraction for tourists from near and far. Our visitors can learn our history and see our traditional water-powered press in action.

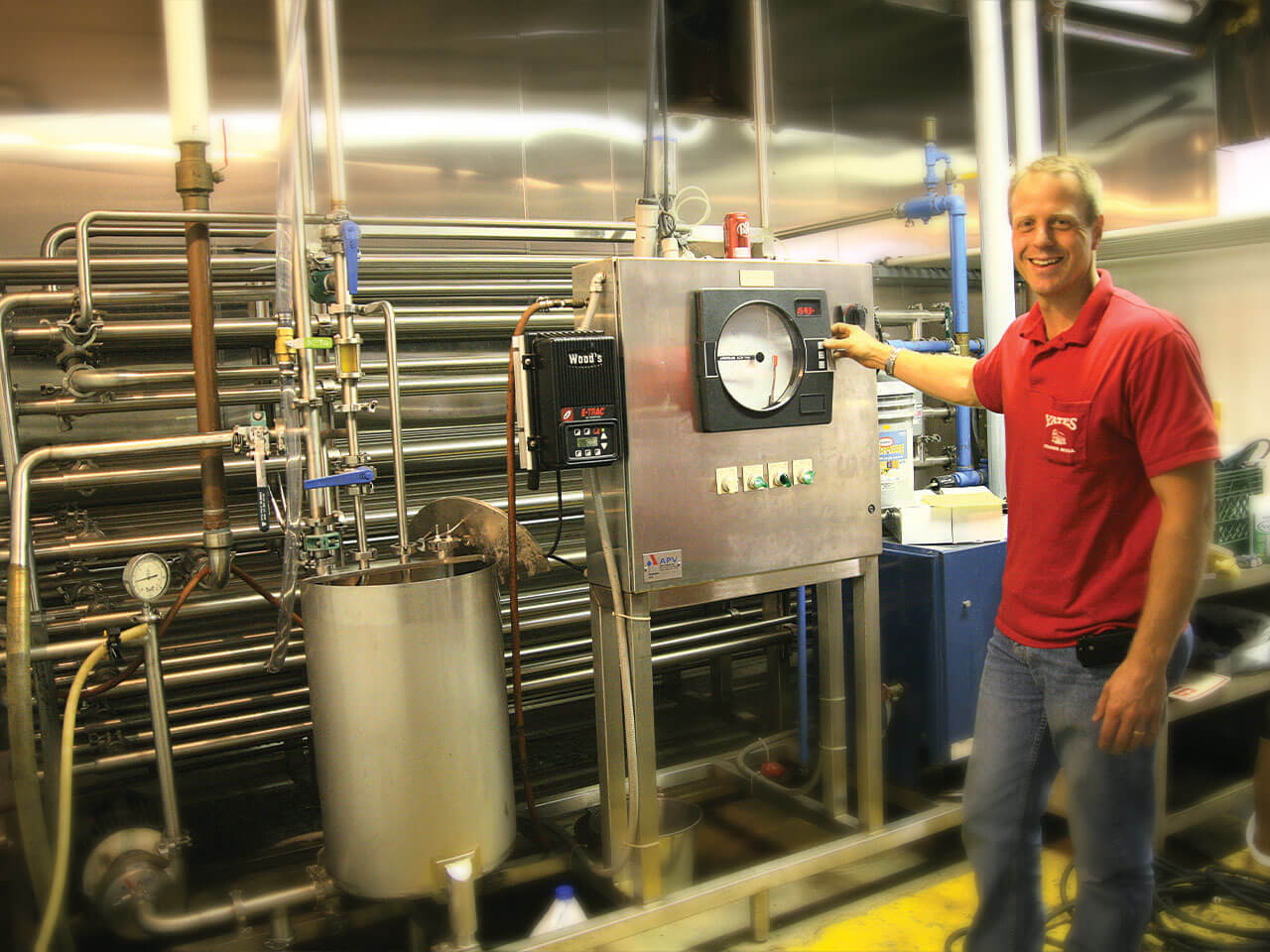

Our iconic 26-inch water turbine provides the power for our press in order to create our premium apple cider, which is all natural and made without preservatives. The water for the turbine is supplied from our dam on the Clinton River. A 58-inch culvert carries the water under the road and into the cider mill. The water then flows through the turbine to provide the power we need to run the press.

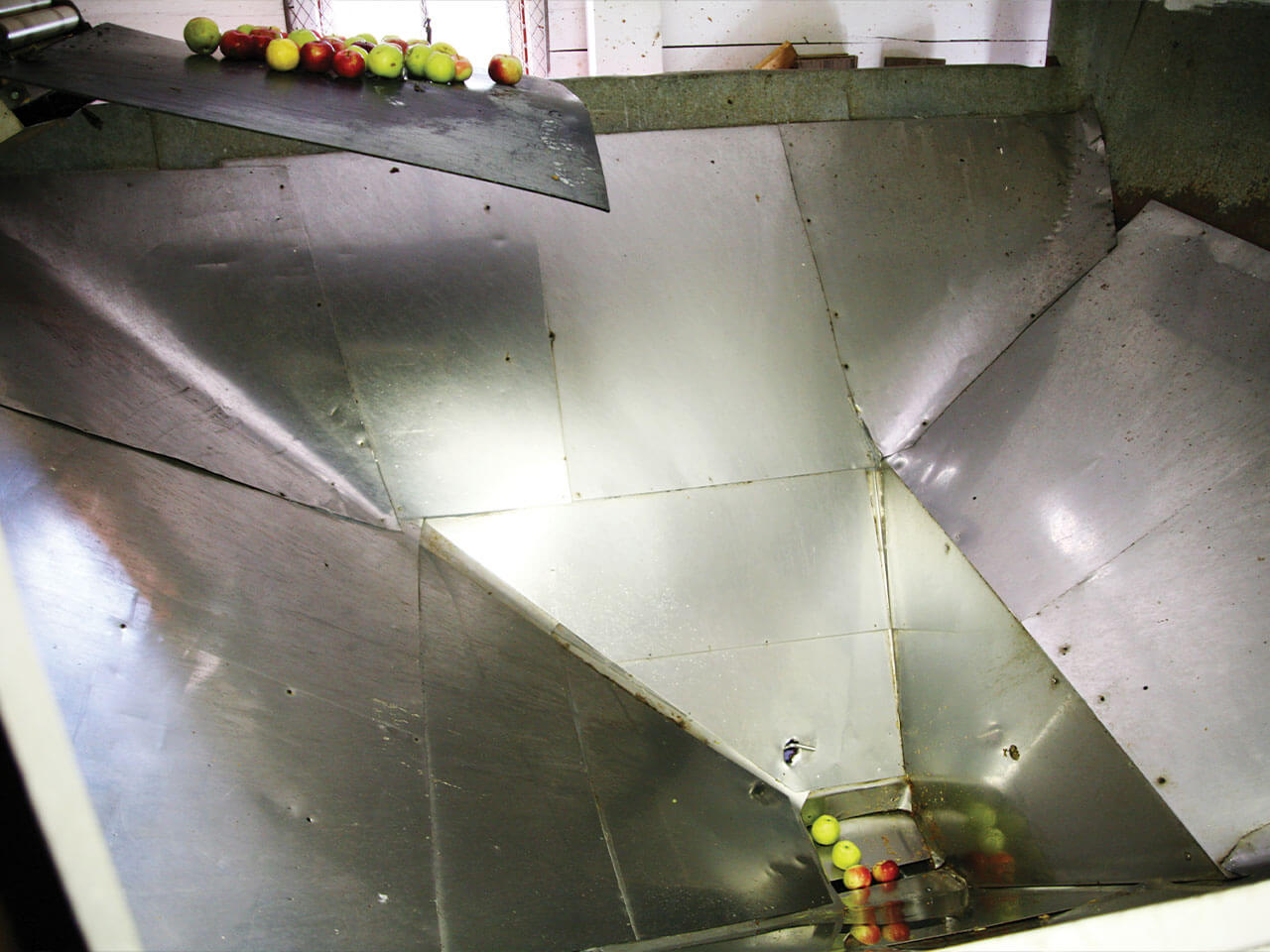

Step 2:

Chopping

Once the hopper has enough apples in it, the press operator manages the grinder equipment from the apple press on the main floor. A trap door on the bottom of the hopper is opened, and a precise amount of apples is ground into small pieces, creating a pulp that looks like chunky applesauce. The press operator then pumps some of the ground apple (pomace) onto the special blankets on the press table. Each blanket is folded and a fresh blanket added on top to prepare for the next layer. This process continues until up to eight blankets are stacked up to make a full table.

Step 3:

Pressing

As the press slowly presses down on the blankets with 50 tons of pressure, the cider comes through the weave in the cloth, leaving the seeds, peelings, and pulp inside the blankets. After the juice is squeezed out, all byproducts are removed into a 20-bushel box and eventually are sent to be composted or used for animal feed.

Our water-powered, double-table press can produce 300 gallons of fresh cider per hour!

Step 4:

Bottling